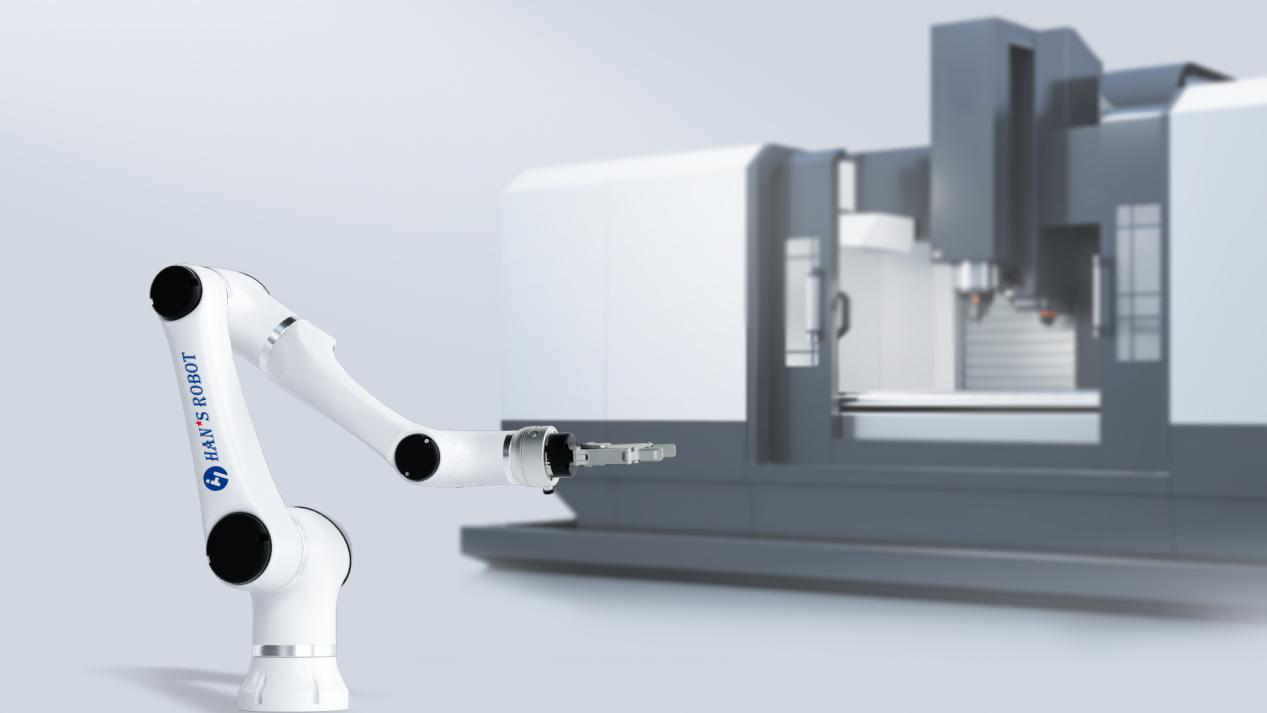

Collaborative robots prove advantageous for loading and unloading. Their advantages include (but are not limited to) high accuracy, flexible deployment, and compact design.

Collaborative robots can achieve high and consistent accuracy for loading and unloading tasks. This minimizes errors, optimizes workflow, and enhances overall efficiency.

Collaborative robots can be easily redeployed to adapt to various loading and unloading tasks with minimal adjustments, thanks to their fast programming capabilities.

With compact size and light weight, collaborative robots can be easily integrated into existing workspaces. They take up small floor space and are easy to deploy.

Collaborative robots can be utilized for 24-hour continuous CNC loading and unloading with high accuracy. They are compatible with various material trays and racks and can meet a variety of workpiece processing needs.

Cobots can also be used for loading and unloading of knife tools grinding. They unload the processed knife tools from the grinding machine and seamlessly load the unprocessed ones. This greatly streamlines the workflow.

Collaborative robots are widely applied in the 3C industry. For tasks such as loading and unloading thermistor tray, which involves chemical hazards and high temperatures, these loading and unloading machines are highly applicable.

Cobots are also applied to the loading and unloading of low-voltage circuit breaker testing. This realizes the automatic detection and packaging of a full range of low-voltage electrical devices.

In the automotive manufacturing industry, cobots can be leveraged for auto parts loading and unloading marking. They can load and unload parts at the same time and avoid the risks of workpiece damage.

Collaborative robots can also load and unload heavier components like seats. They can be used as soon as they are plugged in, which greatly improves efficiency and productivity.

As a leading cobot manufacturer, Han's Robot provides many advantages:

Han's Robot has always been dedicated to developing cobot technologies. At Han's Robot, we have completely self-developed dual-joint modules for optimized singularity and core components including motors, encoders, sensors, etc.

With an accuracy and repeatability of up to 0.02mm, Han's collaborative robots ensure each material they handle is placed with exactness, reducing the risk of damage.

The open source ROS interface allows users to control the robot joints in real time through EtherCAT under the ROS environment. It improves the robot's scalability and allows for controlling the cobot without an additional control box.

Han's collaborative robots are designed to be highly flexible. They can quickly adapt to different work environments and tasks. The cobot cabinets for loading and unloading are maneuverable and responsive to production line adjustments.

Han's collaborative robots are built with safety features that allow them to safely work alongside human workers. The innovative braking design allows them to rebound and stop when encountering any resistance.

Han's cobot solutions support handheld teach pendants, tablets, computers, and other terminals. Graphical programming improves loading and unloading accuracy and efficiency. Integrated with VNC, these cobots achieve remote control and improve safety.