loading...

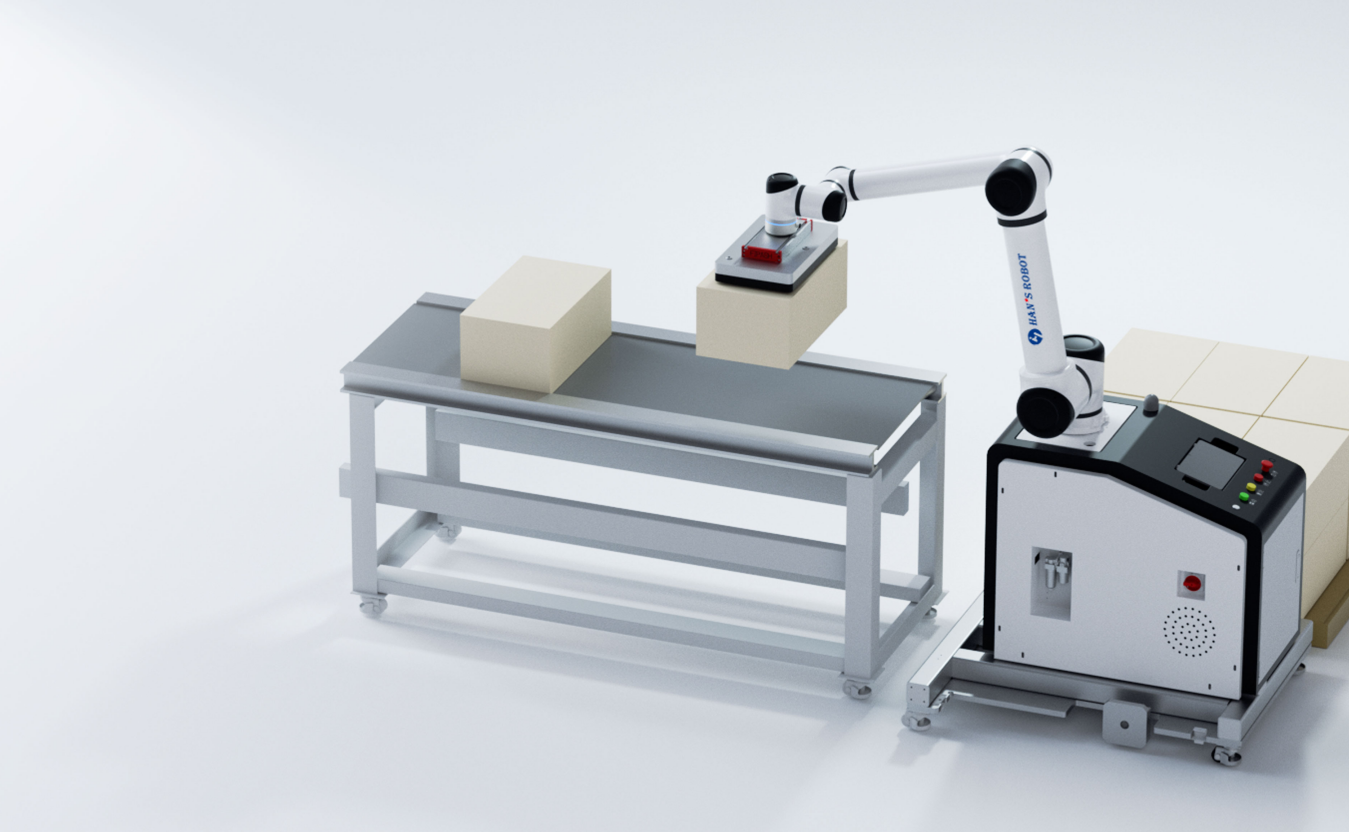

With every new development in the food sector comes an even bigger need for lightning-fast service. Cobot palletizing is a revolutionary method of handling and palletizing that tackles these demands directly. Our expertise at Han's Robot lies in developing state-of-the-art solutions that improve efficiency and output in the food processing industry.

Understanding Cobot Palletizing

Cobot palletizing refers to the use of collaborative robots (cobots) to automate the palletizing process. Unlike traditional industrial robots that operate in isolation, cobots are designed to work alongside human operators, providing flexibility and adaptability without the need for extensive safety barriers.

One of the standout features of our cobot palletizing system is its maximum payload capacity of 35KG. This capability ensures that it can handle a wide range of products, making it suitable for diverse applications in the food industry. By integrating cobot palletizing into production lines, businesses can significantly reduce manual handling, minimizing the risk of injury and increasing efficiency.

Speed and Efficiency Redefined

When it comes to production speed, Han's Robot excels. Our cobot palletizing systems can achieve speeds of up to 13 boxes per minute. This impressive performance translates to time savings of up to 62% for similar tasks compared to conventional methods. In a sector where every second counts, such efficiency gains can lead to substantial improvements in overall output.

Moreover, our systems feature a maximum tool speed of 2.5m/s. This rapid response not only enhances performance but also allows for quick adaptations to changing production needs. With the ability to adjust to different product lines seamlessly, businesses can maintain high levels of productivity while reducing downtime.

Navigating Industry Challenges

The food industry is characterized by its unique challenges, including fluctuating consumer demands and strict quality standards. Cobot palletizing provides a solution to these challenges by offering flexible and efficient handling options. With Han's Robot’s systems, manufacturers can quickly switch between various packaging types, ensuring they meet market demands without compromising on quality.

This flexibility is particularly important in an industry where trends can shift overnight. Our cobot solutions allow businesses to adapt their operations quickly, ensuring they remain competitive and responsive to consumer needs.

Enhancing Workplace Safety and Productivity

Integrating cobot palletizing into food production not only boosts efficiency but also enhances workplace safety. By automating repetitive and physically demanding tasks, our systems reduce the risk of workplace injuries. This allows employees to focus on higher-value activities, contributing to a more engaged and productive workforce.

At Han's Robot, we are committed to providing solutions that not only improve operational efficiency but also promote a safe working environment. Our cobot palletizing technology empowers businesses to leverage automation while prioritizing employee well-being.

Conclusion

Cobot palletizing is reshaping the future of food production, and Han's Robot is proud to be at the forefront of this transformation. Our innovative solutions provide the speed, flexibility, and safety that modern food manufacturers require. With a maximum payload of 35KG and the ability to process up to 13 boxes per minute, our cobot systems are designed to meet the demands of today’s fast-paced industry.

Invest in the future of your operations with Han's Robot and discover how our cobot palletizing solutions can elevate your business. Embrace the advantages of automation, improve your productivity, and stay ahead in the competitive food landscape. Together, we can navigate the challenges of the industry and achieve lasting success.