loading...

TOP1 1800mm

In 2024, Han’s Robot launched multiple collaborative robots with a remarkable arm reach of 1800mm. These include 12KG payload collaborative robots (models: E12, E12-Pro, E12F) and the S Heavy Payload Robot. The 12KG payload collaborative robots(models: E12, E12-Pro, E12F) reinforced Han’s Robot’s leadership in welding and explosion-proof spraying. Meanwhile, S30 and S35 showcased exceptional capabilities in palletizing, combining a 1800mm arm reach with performance on par with industrial robots.

TOP2 35KG

In May 2024, Han’s Robot introduced the S35, a heavy payload palletizing robot. With a rated payload of 35KG and a maximum payload of 40KG, this robot is optimized for large-scale palletizing applications, offering lower energy consumption, enhanced impact resistance, and smoother operation.

Check out our Highlights video to learn more: HAN'S ROBOT S35 Palletizing Master Official Video

TOP3 IEC60601

At the 2024 China International Industry Fair (CIIF), Han’s Robot received multiple certifications from SGS, a globally recognized authority. These included CE-MD, CE-MDR (IEC 60601 CB certification), CE-EMC, North American certification, and functional safety certification. Significantly, achieving the IEC 60601 medical certification signifies Han’s Robot's compliance with internationally recognized standards, affirming its safety and reliability for use in medical and related industries.

TOP4 35%

This year, Han’s Robot made strides in algorithms and motion control. Collaborating with leading CNC enterprises, we optimized the integration of our collaborative robots in CNC machine loading and unloading applications. These efforts have resulted in an overall speed and performance improvement of over 35%, delivering enhanced value and efficiency to users.

TOP5 38%

In palletizing applications, Han’s Robot developed a one-stop intelligent palletizing workstation based on the S Heavy Payload Robot. Achieving up to 13 cycles per minute, with support for stack heights of up to 2.2 meters, the workstation adapts to various stacking configurations. Using high-performance self-developed motors, it handles 2.5 times impact loads, reducing palletizing task times by 38%.

Check out our Highlights video to learn more:Han's Robot S Heavy Payload Robot makes intelligent palletizing more efficient!

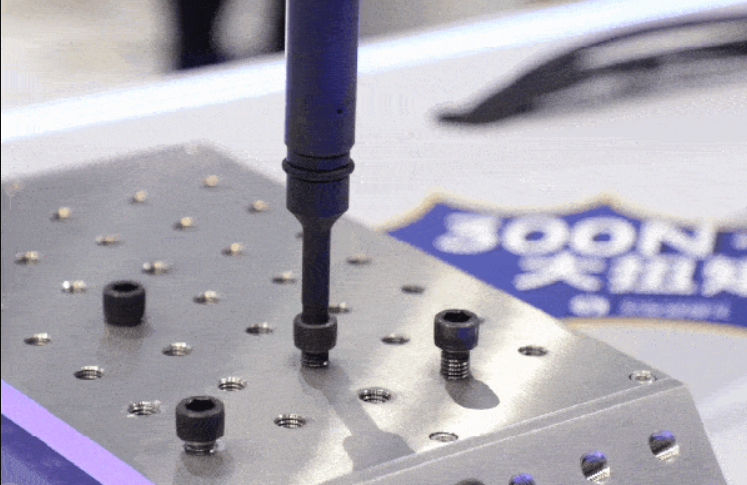

TOP6 300N·m

In screw-tightening applications, Han’s Robot introduced a unique dual-joint module design, featuring an innovative arm structure that withstands immense instantaneous torque during tightening. Capable of handling up to 300N·m, this solution is 7 times more impact-resistant than traditional collaborative robots, meeting the rigorous demands of the automotive manufacturing sector.

TOP7 Welding techniques

In the welding applications, Han’s Robot has taken a practical, application-driven approach to further optimize and upgrade its welding package 3.0. Han’s Robot has made significant advancements in multi-layer and multi-pass welding, laser seam tracking, and features like intermittent welding and teaching offsets, catering to increasingly complex welding needs.

Check out our Highlights video to learn more:Intermittent Welding

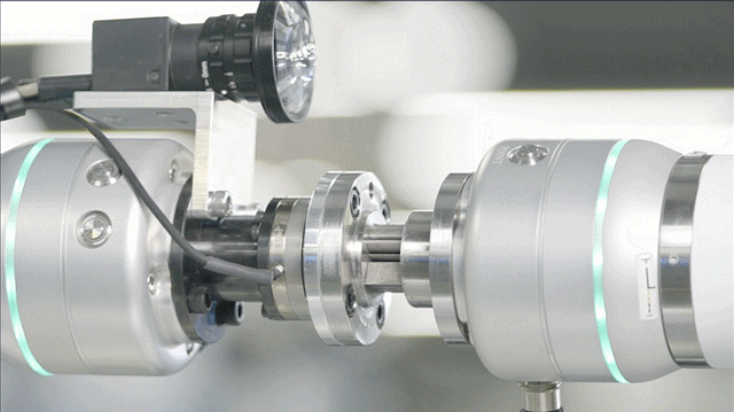

TOP8 Algorithm Breakthroughs

Our high-precision algorithms achieved a 1ms response time. Additionally, we enhanced vibration suppression algorithms, trajectory control algorithms, motion planning algorithms, and force control algorithms(force control fluctuation≤0.5N and drag force ≤5N), significantly strengthening the core capabilities of Han’s collaborative robots.

TOP9 Embodied Intelligence

After mid 2024, Han’s Robot became the only hardware manufacturer specializing in intelligent collaborative robots among Huawei’s strategic partners in embodied intelligence, collaborating with Huawei on a series of initiatives in this field. For example, dynamic insertion applications for rigid components, we elevated collaborative robots has been enhanced from the millimeter level to the sub-100-micron level, achieving a 99.99% success rate in dynamic insertion tasks.

TOP10 Market & Brand Expansion

On the global stage, Han’s Robot showcased its innovations at over 50 professional exhibitions and conferences across the U.S., Mexico, Brazil, Germany, Turkey, the Czech Republic, Japan, South Korea, and India, accelerating its global expansion. In terms of brand promotion, Han’s Robot received prestigious domestic and international awards in 2024, including the Red Dot and iF Design Awards.

Additionally, the company contributed to the development of several national and industry standards, such as G/BT 44589-2024 Technical Requirements for Adaptive Robot Capabilities and the group standard.

TOP11 Ecosystem Partnerships

In 2024, Han’s Robot expanded its ecosystem collaborations. We partnered with Huawei’s Embodied Intelligence Innovation Center, became one of KPMG China's inaugural Top 50 smart manufacturing tech companies, officially joined the Siemens Xcelerator ecosystem, and were selected as a partner in Guangdong's Smart Manufacturing Ecosystem...