loading...

Collaborative robots have been widely applied to welding applications in industries such as automobile manufacturing, machinery production, electronic equipment, aerospace, and more. With advantages like easy operation, flexible deployment, high safety and stability, and self-developed core components, Han's Robot welding cobots have become strong performers in transforming manual welding into automated and efficient welding processes. Our cobot welding solutions meet complex welding requirements, driving flexible production transformation and upgrades in the manufacturing industry.

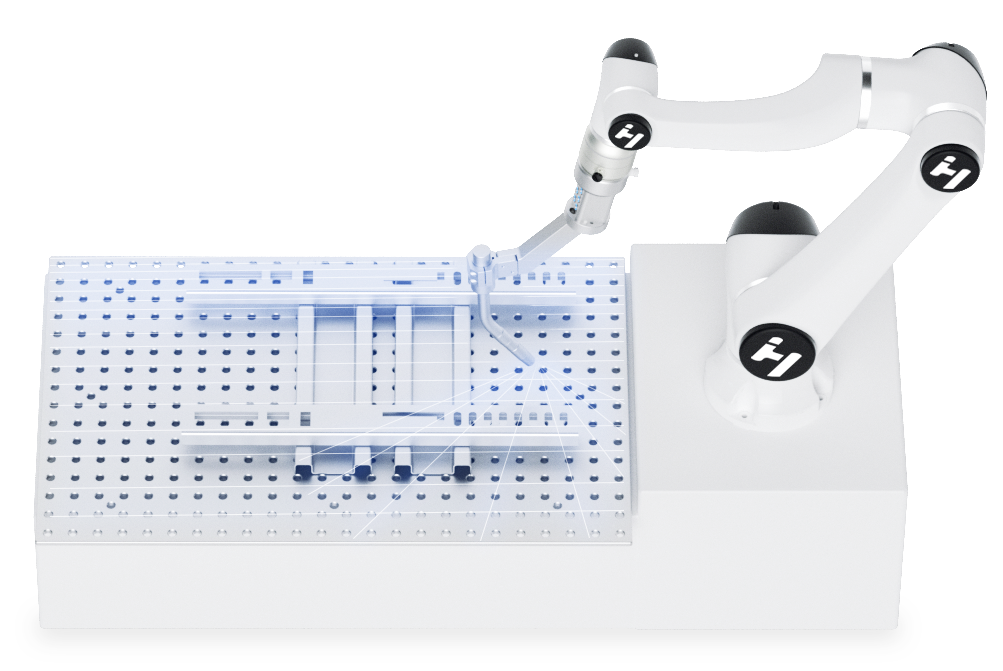

Our cobots adopt a double-joint module design, enabling more flexible movement in cobot welding and supporting complex welding trajectories.

With the advantages of high strength and wear resistance, they can perform stably in cobot welding environments with violent movement or external impact.

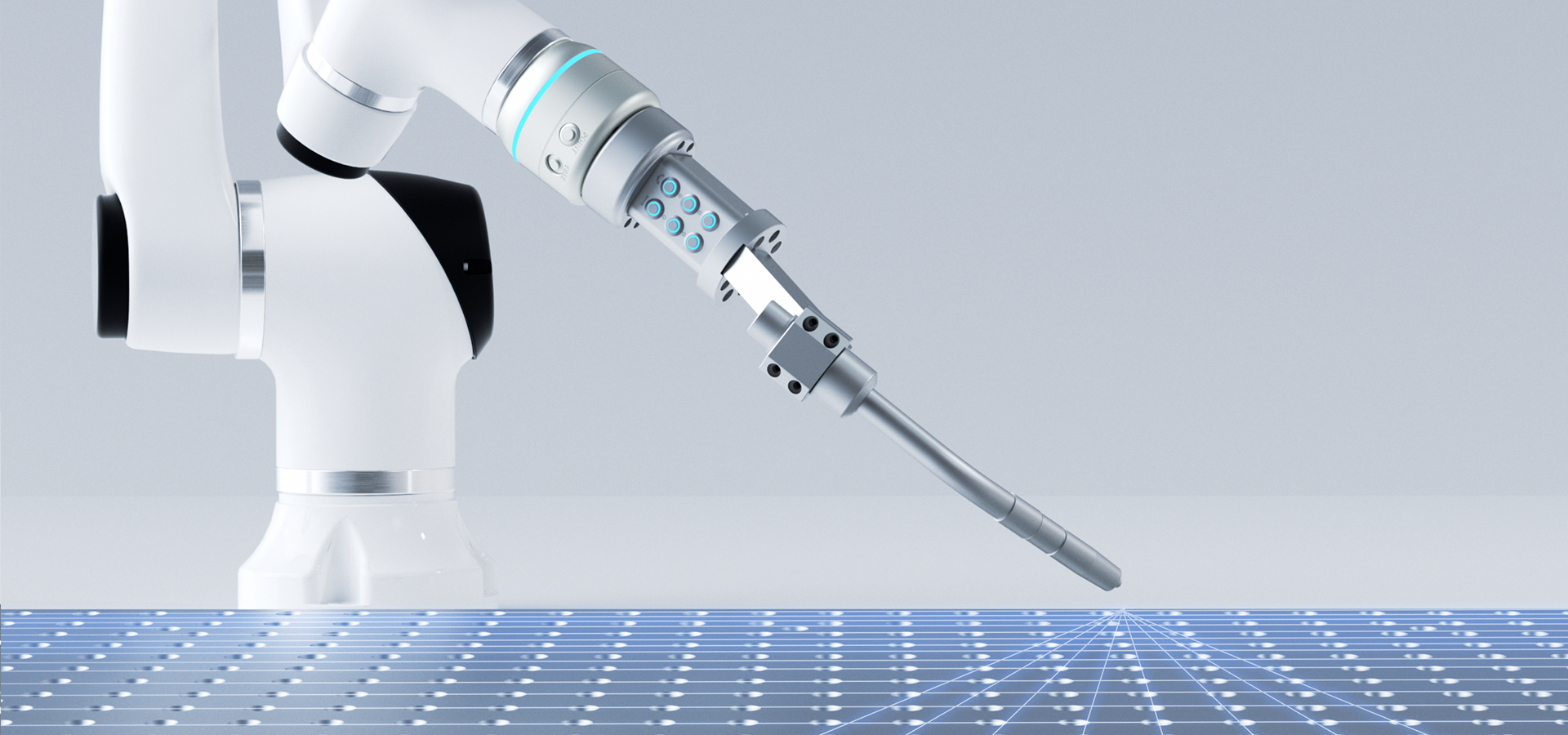

Elfin-Pro collaborative robots adopt advanced motion control algorithms to achieve repeatability to ±0.02mm, ensuring exceptional precision cobot welding. This guarantees both the quality and consistent results, making it an excellent collaborative robot welding solution.

Elfin-Pro supports integrated terminal force control and AI vision for precise, adaptive operations. Its internal wiring and integrated design enable drag-and-drop teaching and visual demonstrations, streamlining collaborative robot welding and making welding automation faster and easier.

Based on EtherCAT ultra-distance deployment, the connecting cable between the collaborative robot body and the electric control box can be extended to 50m, and can be combined with a magnetic base, gantry crane, truss, etc. to achieve flexible handling and is suitable for welding workshops in complex production environments.

Quickly create welding tasks and perform welding operations in just 3 steps.

With arm spread range of 590mm-1800mm, Elfin-Pro collaborative robots can meet different welding requirements.

Adaptable to mainstream welding machines, easy to integrate.