loading...

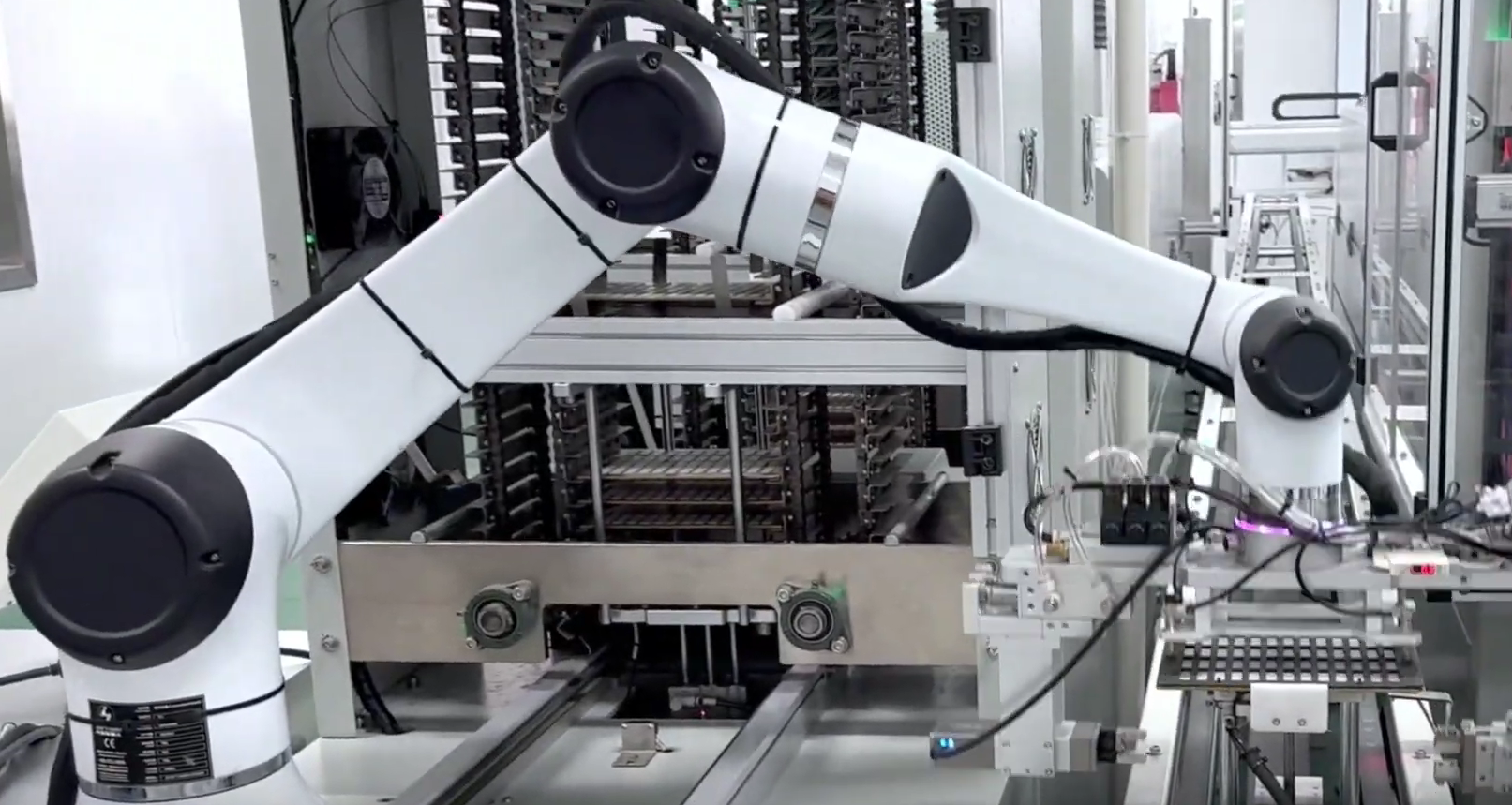

Automation is reshaping the manufacturing industry, especially in areas like loading and unloading tasks where speed, precision, and efficiency are essential. Collaborative robots (cobots) are at the forefront of this change, offering a solution to improve productivity while maintaining safety and flexibility. Han's Robot provides advanced cobots designed to streamline loading and unloading operations.

Benefits of Cobot Automation for Loading and Unloading

Cobot automation improves operational efficiency by reducing the need for manual labor in material handling. Traditional loading and unloading methods can be slow and prone to human error. By incorporating cobots, companies can reduce costs and ensure consistent, high-quality results. Cobots are built to work alongside human operators, offering automation without requiring complex setups or reprogramming. This makes them ideal for repetitive tasks like moving pallets, sorting items, or loading products into containers, all with greater accuracy and speed.

Flexible Use for a Variety of Tasks

One of the main advantages of cobot automation is its flexibility. Han’s Robot cobots can be quickly reprogrammed and redeployed for a wide range of loading and unloading activities. Whether it’s handling different types of materials or moving goods across various stations, cobots can be adapted to meet evolving needs.

The compact, lightweight design of Han's Robot cobots also allows them to be easily integrated into existing workflows. With minimal downtime during transitions, businesses can continue operations smoothly while reconfiguring their automation setup.

Space-Efficient and Practical Design

The compact design of Han's Robot cobots is essential for environments where space is limited. Unlike larger robotic systems, cobots are space-efficient and can operate in tighter areas without disrupting the layout of the workspace. This allows businesses to maximize the available floor space while still benefiting from the efficiency of automated systems.

Their small footprint also means cobots can be placed in locations where traditional robots might not fit, providing flexibility without requiring significant infrastructure changes. This makes them suitable for a variety of production settings, from smaller factories to larger, high-demand environments.

Conclusion

Cobot automation is changing the way businesses handle loading and unloading tasks. With their precise, efficient design, Han’s Robot cobots help companies reduce operational costs, enhance productivity, and minimize human error. Their versatility, combined with a compact footprint, makes them an ideal solution for a wide range of material handling needs. By adopting cobot automation, businesses can improve their operations and better meet the demands of a rapidly changing industry. Han’s Robot provides the tools and technology to help companies stay efficient and competitive in an increasingly automated world.