loading...

Welding joins materials like metal or plastic through fusion using heat and/or pressure. This technique is used in industries such as automotive, agriculture, mining, ships, aerospace, and nuclear. However, welding often comes with its own challenges, from welder shortage to safety concerns. Collaborative robots can tackle these challenges. Read on to learn about the most common welding challenges and find out how advanced welding cobots can overcome these issues.

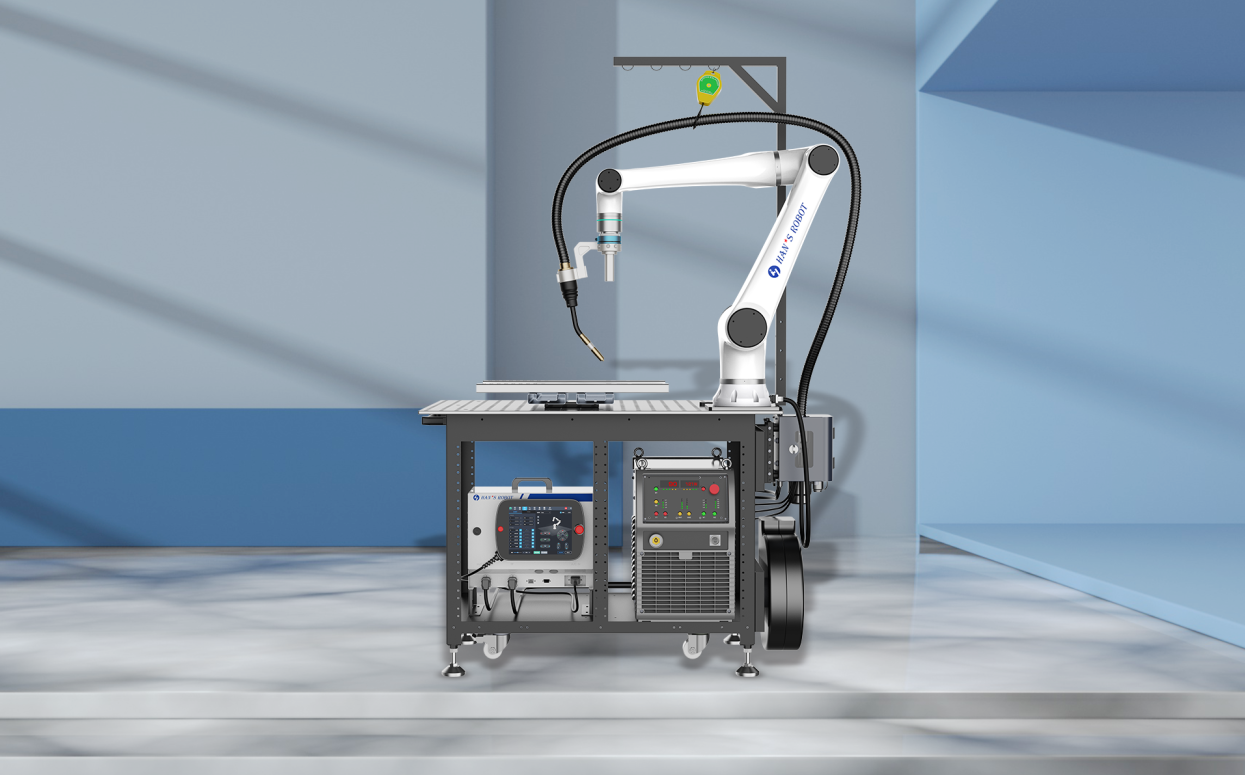

As a specialized type of cobot, collaborative welding robots target various welding tasks. Welding cobot models integrate a power source and tools as end effectors, plus safety features for collaboration. They are easy to program as well, which enhances efficiency and reduces downtime. These help address welding industry challenges.

The welding industry faces challenges with its future workforce. Worker demand will likely outpace the number entering training programs. American Welding Society estimates a shortage of over 300,000 welders by 2028.

This shortage calls for alternatives to human welders like welding cobots. With collaborative welding robots, any worker can perform basic, repetitive welding tasks, allowing expert human welders to focus on intricate duties. Advanced models also allow entry-level welders to perform demanding welding tasks. In this way, welding cobots address the looming shortage.

Over long production cycles, manual welders may tire and lose concentration, leading to variations in weld quality. Minute imperfections can compromise structural integrity and potentially lead to safety concerns down the line.

As humans, it's difficult to maintain absolute precision on repetitive tasks over extended periods. However, a welding cobot is not susceptible to fatigue and can operate without fluctuations in skill level for as many hours per day as needed. Its repeatable precision guarantees quality will remain exceptionally high, shift after shift.

Industrial welding robots typically require extensive reprogramming between jobs due to workpiece variability. Highly complex code definition drives up programming time and production downtime.

In comparison, welding cobot models offer users efficient reprogramming via teaching pendants, enabling rapid reconfiguration between tasks. Operators easily transition cobots through visual demonstrations or manual guidance, minimizing non-productive time. This convenient flexibility salvages costly hours otherwise lost during changeovers.

The welding process involves safety hazards like exposure to heat, sparks, and hot metal. Traditional welding methods can place workers at risk of injury. A welding cobot enables automated cobot welding in the distance, eliminating unsafe interactions. Collaborative robots in manufacturing prioritize worker protection.

Drag-and-Drop Teaching

Setting welding sequences is simplified through drag-and-drop teaching. Elfin-pro facilitates the intuitive guidance of the welding torch to the target welding point. This streamlined approach reduces training times and empowers independent process adjustments.

Better Environmental Adaptability

Most welding robots are restricted to fixed stations due to wiring and stability needs. Elfin-Pro welding cobot provides maximum versatility through Ethernet connections extending 50 meters between controllers. Its magnetic and overhead mounting solutions integrate seamlessly with diverse production layouts.

Graphical Programming

Traditional syntax demands coding expertise that most welders lack. Elfin-Pro places programming control directly in operators’ hands through 3D point-and-click workflows. Integrated menus adjust voltage, wire speed, and more with ease. Process development remains straightforward and accessible.

Overall, welding cobots help overcome challenges around welder shortfall, inconsistent quality control, and rigidity faced in traditional welding methods. Collaborative robots such as Han’s Robot’s premier model, the Elfin-Pro, achieve boosted productivity, higher reliability, and safer operations through interactive programming on a modular platform. As a trusted partner around the globe, we deliver dependable solutions for various industries internationally. Browse our website to discover our full lineup of intelligent robotics.