loading...

The implementation of collaborative robots, also known as cobots, is causing an adjustment in the way firms function as the manufacturing industry continues to undergo transformation. The revolutionary potential of these cutting-edge technology is something that we at Han's Robot are willing to acknowledge. We are able to gain a better understanding of the major benefits that cobots in manufacturing offer if we concentrate on their capacity to improve accuracy and flexibility.

Enhancing Precision and Reducing Errors

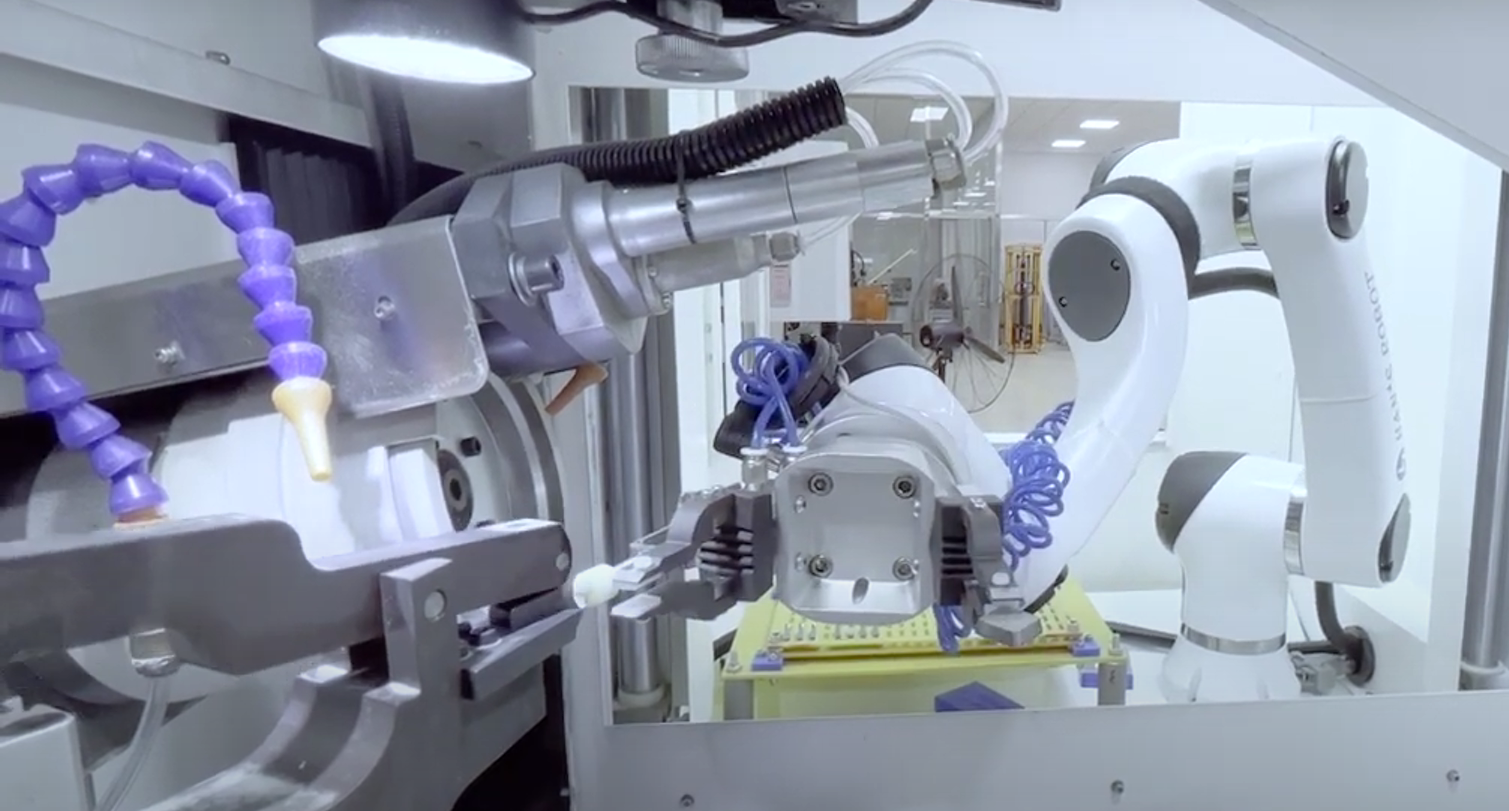

In manufacturing, accuracy is paramount. Errors can lead to costly delays and wasted resources. Cobots in manufacturing provide a solution to this challenge through their high precision in tasks such as loading and unloading. Han's Robot cobots are designed to perform these repetitive tasks with exceptional accuracy, significantly minimizing the likelihood of mistakes.

This precision not only ensures that products meet quality standards but also streamlines the entire production process. With fewer errors, manufacturers can maintain a steady workflow, reducing downtime and increasing output. The seamless integration of cobots into existing systems allows companies to enhance operational efficiency while maintaining high-quality production standards.

Flexibility to Adapt to Changing Needs

The versatility of cobots in manufacturing is yet another significant advantage provided by these machines. In the fast-paced economy of today, manufacturers need to be nimble in order to respond to their customers' ever-changing demands. This is an area in which Han's Robot cobots thrive, as they are able to quickly reconfigure themselves for a variety of activities with very minimum alterations to their code.

This adaptability is essential for manufacturers, as they may need to alter product lines or tweak their strategies in response to changes in the market. Companies are able to ensure that they are constantly prepared to tackle new problems by utilizing collaborative robots. This allows them to avoid substantial downtime or the investment in new equipment. In a market that is always shifting, the capacity to quickly redeploy cobots is a competitive advantage that can be gained significantly.

Conclusion

In summary, cobots in manufacturing represent a significant leap forward in operational efficiency. At Han's Robot, we understand that the integration of collaborative robots is more than a technological upgrade; it’s a strategic decision that can redefine how businesses operate. By enhancing accuracy and providing the flexibility to adapt, our cobots empower manufacturers to thrive in a competitive landscape. As we move forward, embracing the potential of collaborative robots will be essential for companies looking to maintain their edge. Han's Robot is dedicated to supporting this journey, offering advanced solutions tailored to meet the unique needs of each manufacturer. Together, we can build a more efficient, accurate, and responsive manufacturing future.