loading...

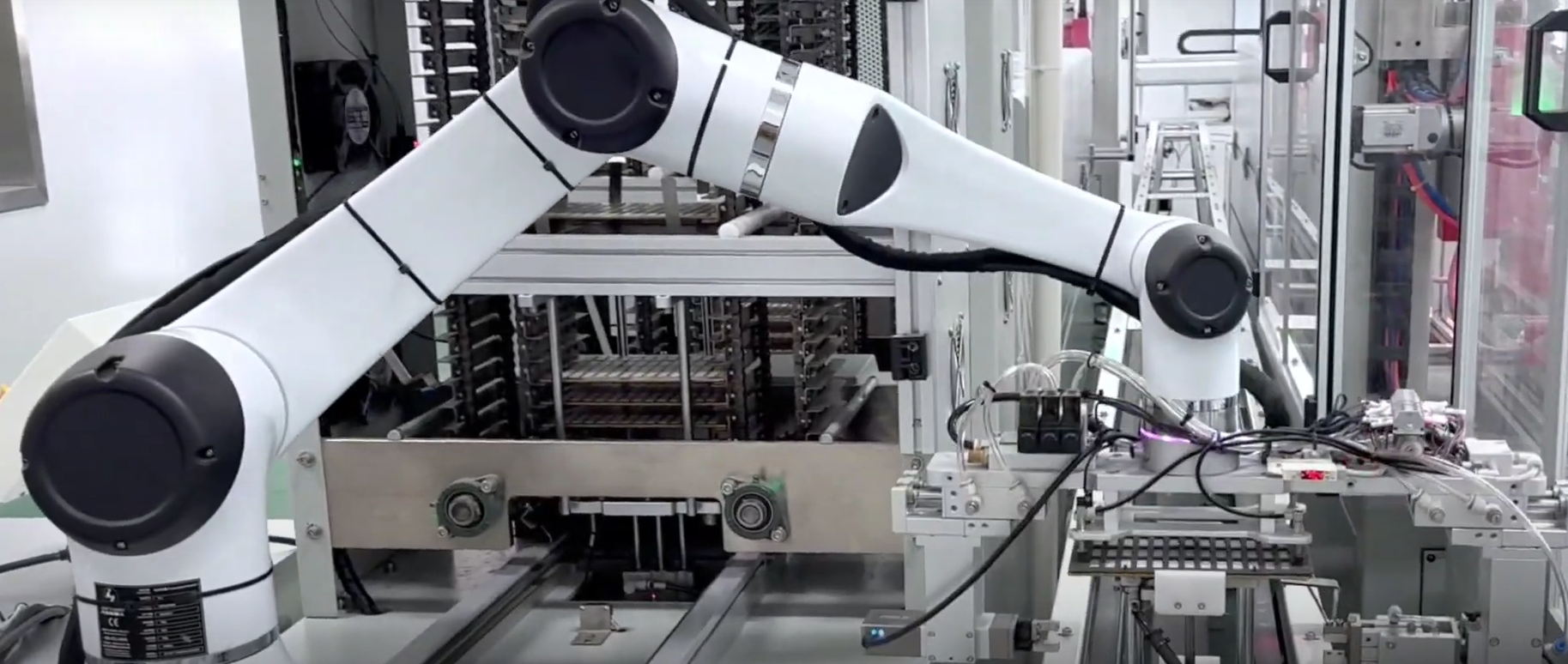

The manufacturing industry is undergoing significant changes with the introduction of collaborative robots, or cobots. At Han's Robot, we understand the critical role these machines play, especially in sectors like the 3C industry (computer, communication, and consumer electronics). Our focus is on how cobots can optimize processes, particularly in tasks such as loading and unloading thermistor trays, which often involve chemical hazards and extreme temperatures.

Enhancing Workplace Safety

A primary benefit of integrating cobots in manufacturing is the enhancement of workplace safety. Tasks involving thermistor trays can pose serious risks due to exposure to hazardous chemicals and high temperatures. By deploying Han's Robot cobots, manufacturers can significantly reduce the potential for workplace accidents. These collaborative robots take on the more dangerous aspects of loading and unloading, allowing human workers to engage in safer, more strategic roles.

This shift not only protects employees but also contributes to a more efficient workflow. With cobots handling hazardous tasks, the likelihood of disruptions due to accidents is minimized, leading to a smoother production process. Safety and efficiency are no longer mutually exclusive; they can coexist harmoniously in a modern manufacturing environment.

Flexibility and Adaptability in Operations

Another compelling aspect of cobots in manufacturing is their flexibility. Han's Robot cobots are designed for easy programming and rapid redeployment, making them ideal for tasks that change frequently, such as those in the 3C industry. The ability to quickly adapt to different loading and unloading tasks means that manufacturers can respond more effectively to fluctuating market demands.

This adaptability is crucial in maintaining operational efficiency. When production lines need to shift focus, our cobots can adjust with minimal downtime, ensuring that manufacturers remain competitive. This capability not only enhances productivity but also allows for better resource management within the manufacturing process.

Driving Innovation and Quality

Incorporating cobots in manufacturing is also about fostering innovation and maintaining high-quality standards. At Han's Robot, we are committed to providing solutions that not only improve efficiency but also enhance the overall quality of production. Our cobots ensure that tasks like loading and unloading thermistor trays are performed with precision, reducing the risk of errors that can affect product quality.

By automating repetitive and hazardous tasks, manufacturers can allocate more resources to research and development, leading to innovative products and processes. This focus on quality and innovation positions companies to better meet customer expectations and market demands.

Conclusion

In a nutshell, the integration of cobots in manufacturing represents a significant advancement in operational strategy. At Han's Robot, we believe that our collaborative robots can transform how manufacturers approach safety, efficiency, and quality. The ability to handle hazardous tasks like loading and unloading thermistor trays not only protects workers but also enhances overall productivity. As the manufacturing landscape continues to evolve, embracing cobots will be essential for companies seeking to stay competitive. By investing in Han's Robot cobots, manufacturers can create a safer, more efficient, and innovative production environment. This transition is not just about adopting new technology; it’s about redefining the future of manufacturing.