loading...

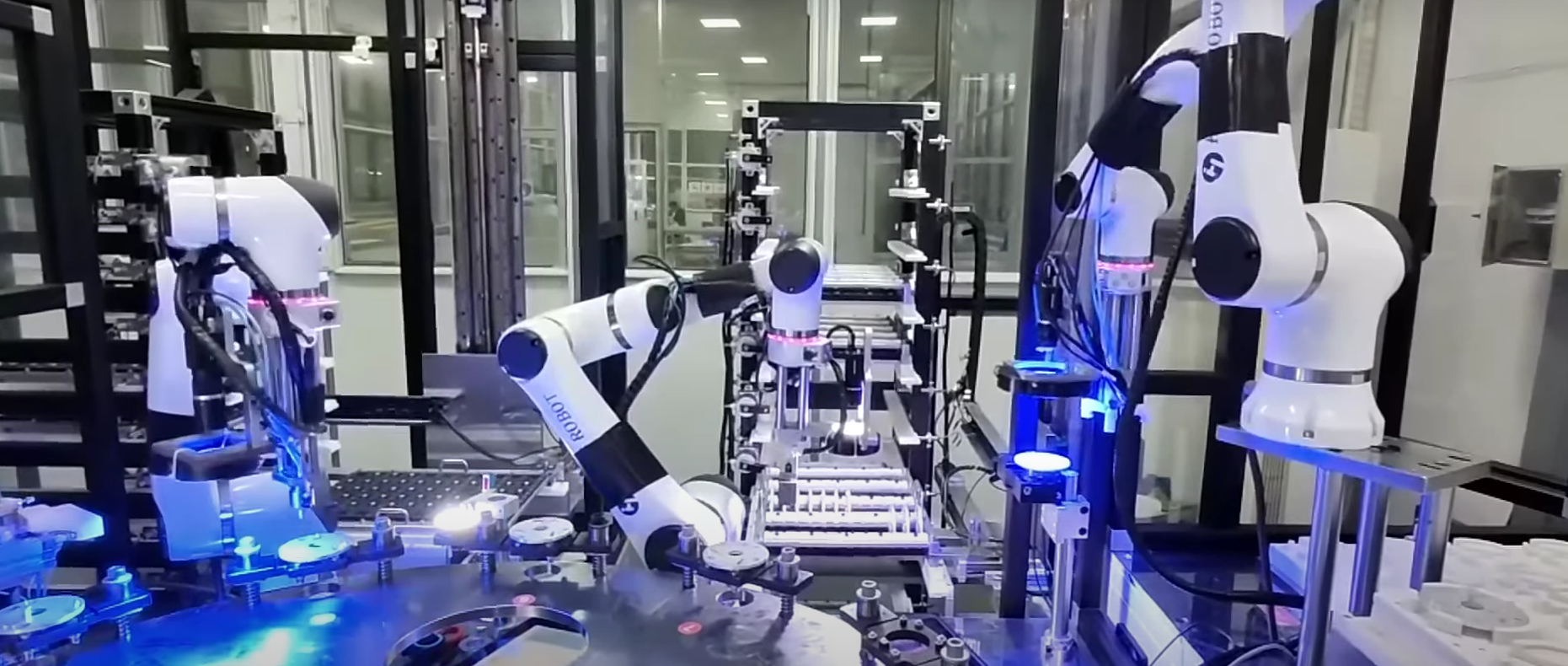

At Han's Robot, we understand the vital impact that collaborative robotics have on the automotive industry, particularly in the assembly process. As manufacturers strive for greater efficiency and productivity, the deployment of collaborative robots has become a game-changer. This article examines how our advanced robots enhance operations, focusing on loading and unloading tasks for components such as Volkswagen seats.

Streamlining Seat Assembly Processes

The assembly of vehicles involves numerous complex tasks, one of which is handling heavier components like seats. The introduction of collaborative robotics in this area has transformed traditional methods. Our collaborative robots can quickly and efficiently load and unload seats, significantly reducing the time spent on these tasks.

This capability not only speeds up the assembly line but also minimizes the physical strain on human workers. By automating the handling of heavy components, companies can ensure that their workforce is focused on more intricate tasks that require human dexterity and decision-making. This shift leads to a more balanced and productive work environment.

Instant Deployment for Enhanced Productivity

One of the standout features of collaborative robotics is their ease of deployment. Our robots can be operational immediately after being plugged in, which greatly enhances efficiency. This rapid setup means that manufacturers can quickly adapt to changes in production schedules or product designs without significant downtime.

This immediacy is particularly beneficial in a fast-paced industry like automotive manufacturing, where demand can fluctuate and timelines are tight. By utilizing collaborative robots, businesses can respond more swiftly to market needs, ensuring they maintain a competitive edge.

Benefits Beyond Efficiency

While the efficiency gains from collaborative robotics are significant, the benefits extend beyond productivity. The implementation of our collaborative robots also enhances workplace safety. By handling heavy components like seats, these robots reduce the risk of injury for human workers. This focus on safety is crucial in environments where the physical demands of the job can lead to strain or accidents.

Moreover, our robots are designed to work alongside human operators, creating a collaborative environment that fosters teamwork. This harmonious interaction not only boosts productivity but also improves job satisfaction among employees, as they are relieved from the more strenuous aspects of assembly work.

Conclusion

The integration of collaborative robotics into automotive assembly processes represents a significant leap forward in operational efficiency, safety, and adaptability. At Han's Robot, we are committed to providing innovative solutions that meet the evolving demands of the automotive industry. As the landscape of manufacturing continues to change, the role of collaborative robots will only grow in importance. By adopting our advanced technology, companies can streamline their operations, enhance safety standards, and improve overall productivity. Embrace the future of automotive manufacturing with Han's Robot and experience the transformative power of collaborative robotics today!