loading...

The industrial landscape is evolving, and firms are under pressure to increase efficiency, cut costs, and satisfy market needs. In this transformation, the integration of collaborative robots (cobots) into manufacturing environments is groundbreaking. Redefining the automation paradigm with efficient, flexible, and cost-effective solutions is Han's Robot's goal. Automation relies on traditional robots, but they have inflexible programming, limited adaptability, and high setup costs. Conversely, collaborative robots collaborate seamlessly with humans to promote shared tasks. Manufacturing can rethink automation, efficiency, and labor relations due to this robotics transition.

A New Era of Flexibility in Manufacturing

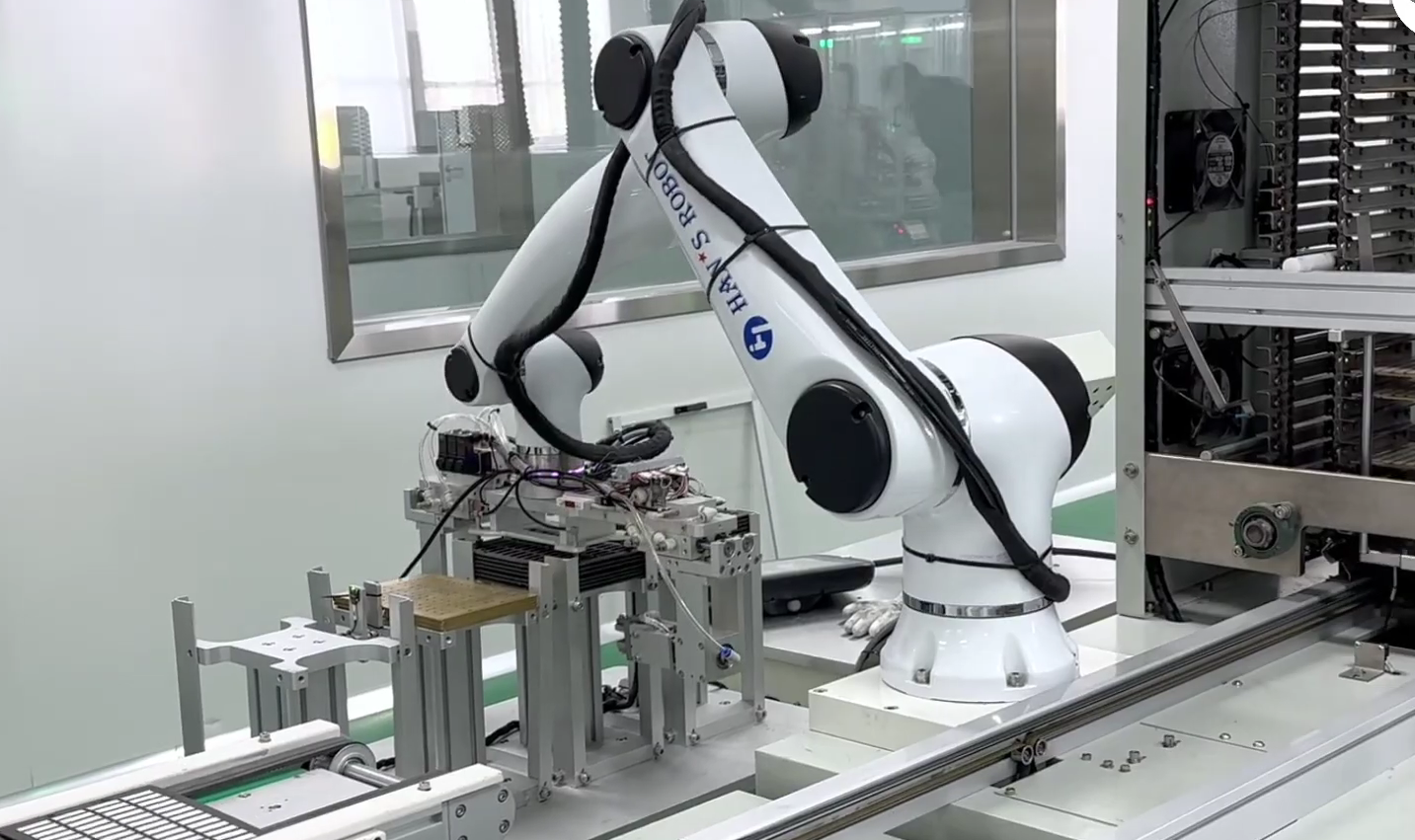

One of the most significant advantages that collaborative robotics bring to manufacturing is their flexibility. Unlike traditional industrial robots, which often require long reprogramming times to switch between tasks, cobots are designed for quick deployment and easy reconfiguration. For example, in industries like CNC machining or electronics manufacturing, where production runs can frequently change, cobots allow companies to adapt quickly to new requirements without significant downtime.

Han’s Robot’s cobots, which excel in environments where the demands for precision and adaptability are high, highlight the transformative potential of this technology. Instead of investing in costly, specialized machines for each new task, manufacturers can now deploy a single collaborative robot across multiple stages of production. This adaptability is particularly valuable for small to medium-sized enterprises (SMEs) that need to maintain a competitive edge while working within tight budget constraints.

Enhancing Worker Roles, Not Replacing Them

Perhaps one of the most commonly held misconceptions about automation is that it will lead to mass job displacement. However, collaborative robots are designed to work alongside humans, not replace them. By taking over repetitive, strenuous, or dangerous tasks, cobots allow workers to focus on higher-value activities—those that require decision-making, problem-solving, or creativity.

For example, in hazardous environments where workers might be exposed to high heat or toxic chemicals, such as the handling of thermistor trays in electronics manufacturing, cobots can take over these tasks. This not only reduces human exposure to risk but also ensures that workers are able to engage in more fulfilling and less physically demanding aspects of the production process.

This shift in how workers interact with machines fosters a collaborative environment where human skills and robotic precision complement each other. In industries like automotive and electronics, where safety and precision are paramount, the integration of collaborative robots leads to improved working conditions and more sustainable practices. Workers can perform their jobs with less stress and fatigue, knowing that the cobot is there to handle the heavy lifting.

Cost-Effectiveness: Making Automation Accessible to All

One of the primary challenges that many manufacturers face when considering automation is the initial investment. Traditional industrial robots can be prohibitively expensive, especially when factoring in installation, maintenance, and downtime for reconfiguration. Han's Robot has addressed this issue by developing cost-effective cobots that can be integrated into existing workflows with minimal disruption.

The modularity and user-friendly nature of cobots mean that companies do not need to overhaul their entire manufacturing process to reap the benefits of automation. Han’s Robot’s cobots come with intuitive programming interfaces and low maintenance requirements, making them accessible not only to large enterprises but also to smaller companies that may not have the resources to invest in more expensive automation solutions.

In industries where operational efficiency is critical, cobots provide manufacturers with the opportunity to automate key tasks without incurring the significant upfront costs typically associated with industrial robots. This democratization of automation allows smaller businesses to stay competitive in an increasingly automated world.

Increased Safety and Reduced Risk in High-Stakes Environments

Manufacturing often involves risky environments, where workers are exposed to dangerous machinery, hazardous chemicals, or extreme temperatures. In such cases, cobots from Han’s Robot can play a pivotal role in reducing workplace injuries and maintaining a safe working environment.

Take, for example, the process of handling thermistor trays in electronics manufacturing, which often requires dealing with high-temperature conditions. By deploying collaborative robots for these tasks, manufacturers can keep human workers out of potentially harmful situations. Cobots also help eliminate the strain of repetitive tasks, which can lead to fatigue and injuries over time.

Furthermore, because cobots are designed to work alongside humans without the need for physical barriers, they offer a unique blend of safety and collaboration. They can stop or slow down their actions if they detect an obstruction, ensuring that no accidents occur when workers are in proximity. This level of safety makes collaborative robots a valuable addition to any manufacturing floor, where the well-being of employees is just as important as efficiency.

Conclusion

Collaborative robots are changing how we view the interaction between humans and machines, not simply in production. Collaborative robots augment human labor rather than replace it. Started with Han's Robot, this transition gives businesses the tools they need to compete in an automated world. Cobots are helping manufacturers address present production difficulties and prepare for future ones by boosting efficiency, worker safety, and cost. Ultimately, people and robots will work together to produce more agile, efficient, and safe production settings. With this relationship, innovation is limitless, and Han's Robot is ready to lead this exciting new chapter in industrial automation.